Inspection Services

Need Any Help?

Partner with INSPECTA Middle East for inspection services. Contact us today to learn more about how we can support your business with our solutions.

+20 034265180

+20 127 613 2866

Inspection Services

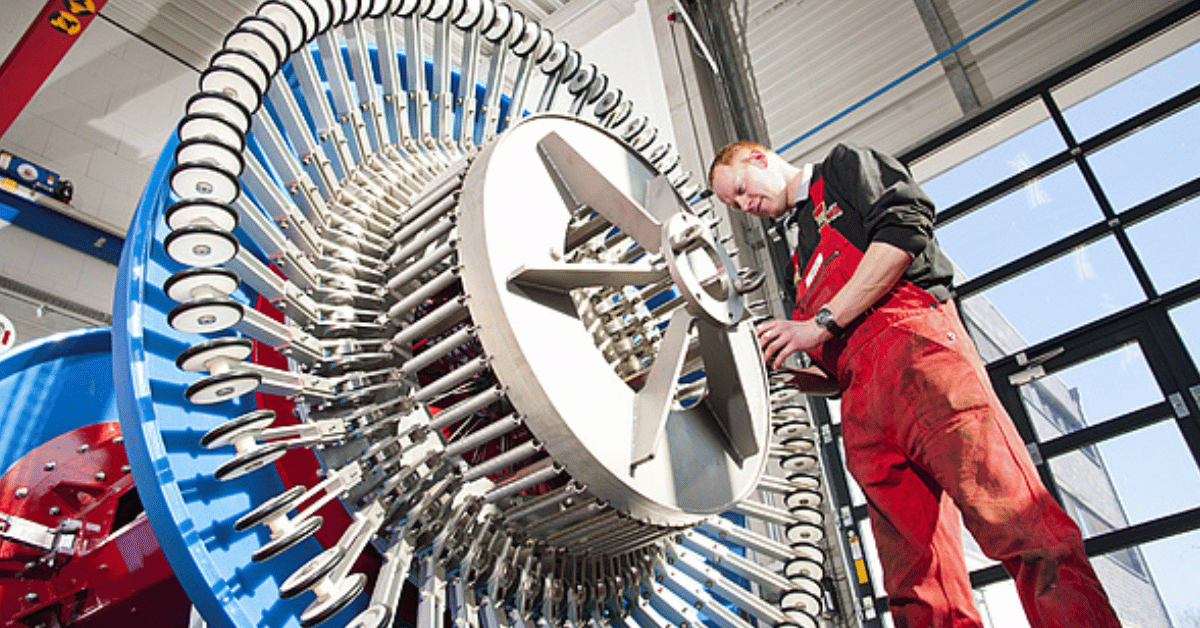

At INSPECTA Middle East, we understand that the integrity of your assets is paramount to the success and safety of your operations. Our inspection services are designed to provide comprehensive, reliable assessments that help you maintain the highest standards of quality and safety in your industry. With over 32 years of experience, we bring unmatched expertise and precision to every inspection, ensuring that your equipment and infrastructure meet all regulatory requirements and operational demands.

Holiday Detection

Holiday Detection is a non-destructive test performed on non-conductive coatings applied to conductive substrates, such as pipelines. Outlined by test methods like ASTM G62, a holiday detector uses a charged electrode passed over a coating. When a holiday is encountered, current flows from the electrode into the conductive substrate below. The current returns to the detector through a ground wire, completing the circuit and triggering an alarm, alerting the inspector to the defect

Positive material identification (PMI)

Positive material identification (PMI) is essential to verify that the materials supplied are in accordance with the appropriate specifications, to ensure that the chemical composition of the metal parts has the appropriate percentage of the essential elements, following the physicochemical compositions of manufacture, standards or defined by the buyer.X-ray fluorescence technology (XRF) provides one of the simplest, most economic and accurate analytical methods for the determination of the chemical composition of many types of materials. It is non-destructive and reliable, requires no, or very little, sample preparation

Replica Test

Replication metallography is a non-destructive sampling procedure which records and preserves the topography of a metallographic specimen as a negative relief on a plastic film. The microstructural replica can be examined using a light microscope or Scanning Electron Microscope (SEM) for subsequent analysis.The uses for replica is to : Microstructure evaluation ,Creep damage assessment – mostly on high-pressure and high-temperature equipment such as steamlines, boilers and reactors,Thermal degradation of the materials – mostly on stainless steels in high-temperature equipment, where detrimental precipitation and the Degree of Sensitization (DOS) can be assessed. Thermal degradation can also occur during unwanted high-temperature exposure, such as fire damage or hot spots,Failure analysis/crack analysis,Hydrogen Embrittlement (HE) ,Stress Corrosion Cracking (SCC)

Intergranular Corrosion (IGC) & Graphitization .

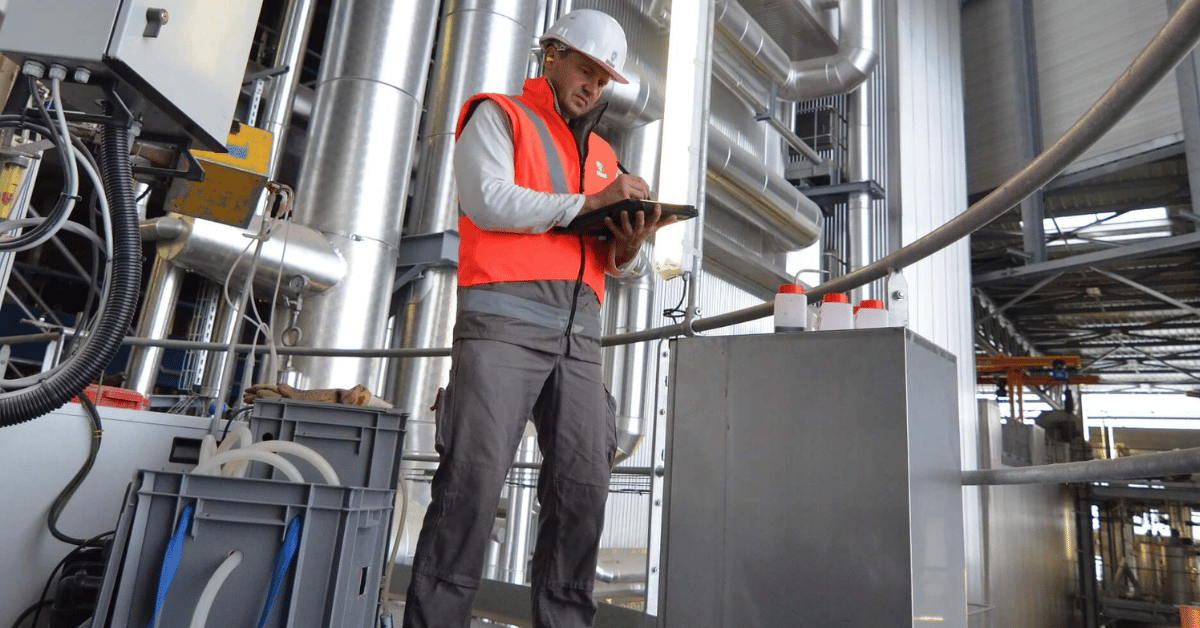

Our Inspection Process

- Consultation and Planning: We start by understanding your specific needs and challenges to tailor our inspection services accordingly.

- Onsite Inspections: Our certified inspectors visit your site, equipped with the latest technology to perform detailed evaluations.

- Analysis and Reporting: After the inspection, we analyze the data and compile a comprehensive report outlining our findings, recommendations, and any necessary corrective actions.

- Follow-Up Support: We provide ongoing support to ensure that any issues are resolved and that your operations remain compliant and safe.

Why Choose INSPECTA Middle East?

At INSPECTA Middle East, our inspection services are more than just a checkbox on your compliance list—they are a crucial part of your operational strategy. We combine our deep industry knowledge with cutting-edge inspection techniques to deliver services that not only meet but exceed industry standards. Whether you’re looking to prevent potential issues, extend the life of your assets, or ensure compliance with stringent regulations, our inspection services are tailored to meet your specific needs.

FAQ's

Q: How often should inspections be conducted?

A: The frequency of inspections depends on the industry, asset type, and regulatory requirements. We can help you establish an appropriate inspection schedule.

Q: What happens if an issue is found during an inspection?

A: If an issue is identified, we will provide a detailed report with recommendations for corrective actions. We also offer follow-up support to help implement these solutions.

Q: Can inspections be performed without shutting down operations?

A: Yes, many of our inspections can be conducted while your operations continue, minimizing disruption.