Heat Treatment Services

Need Any Help?

Partner with INSPECTA Middle East for inspection services. Contact us today to learn more about how we can support your business with our solutions.

+20 034265180

+20 127 613 2866

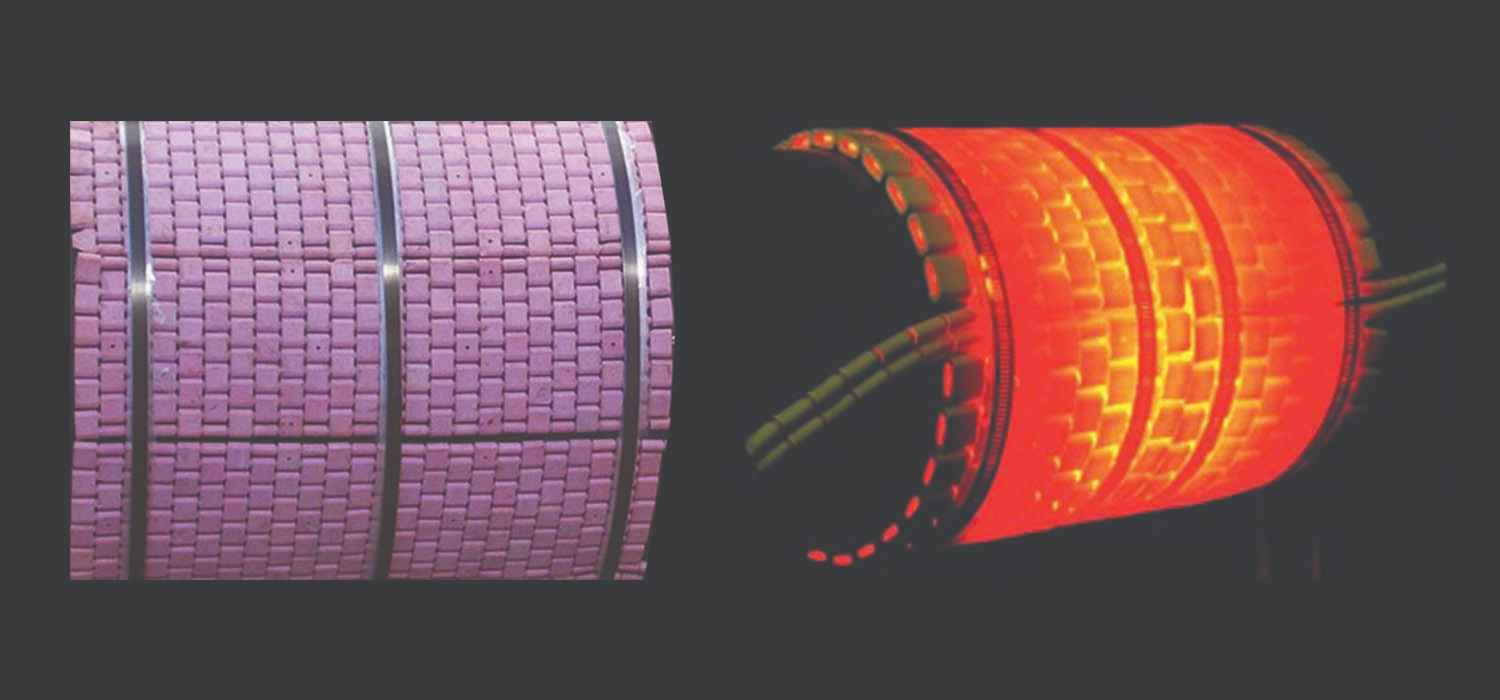

Heat Treatment

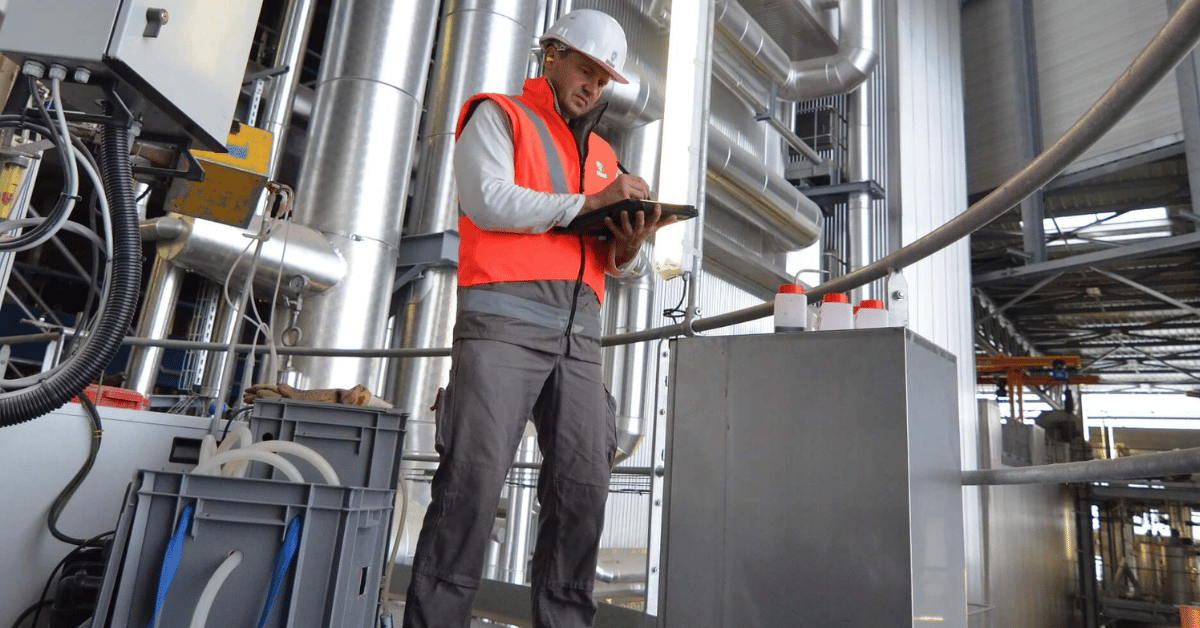

At INSPECTA Middle East, our Heat Treatment Services are designed to optimize the mechanical properties of metals and alloys, ensuring they meet the rigorous demands of industrial applications. Heat treatment is a critical process in industries like oil and gas, petrochemicals, power plants, and heavy manufacturing, where material performance under extreme conditions is crucial.

What is Heat Treatment?

Post weld heat treatment (PWHT) refers to a heat treatment of machined surfaces/welds after undergoing machining/welding to accommodate their mechanical and chemical properties. Welding causes residual stresses that cause long-term structural deterioration in a structure. Also, in more complex or larger parts/structures, increasing stresses increase.

When joining metals during the welding process, different degrees of hardening occur, especially in the heat affected zone by the effects of the weld metal patch, depending on the carbon content in the metals. Residual stresses in the structure increase significantly due to solidification and melting, and their magnitude becomes almost equal to the main distribution flow spread.

Typically, PWHT is used to reduce residual stresses and resist brittle fracture. In addition, PWHT can also lead to increased material strength and duration of hardness. Voltage suppression and post-start are the most commonly used PWHT transmissions. The application and code requirements and service environment are primarily geared towards PWHT.

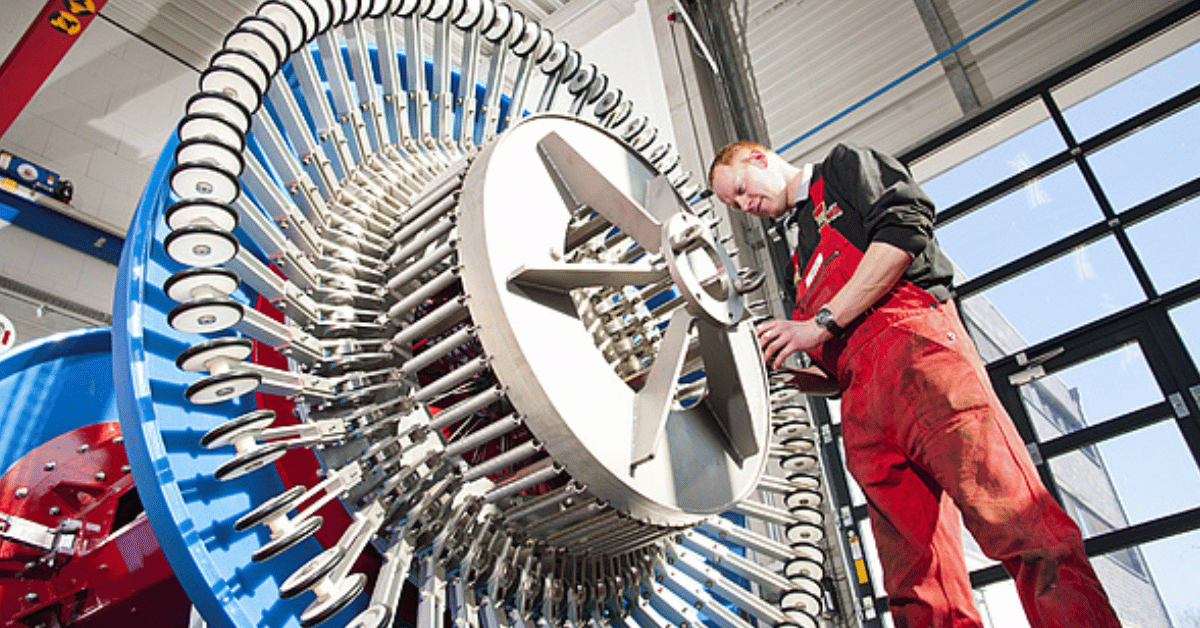

Our Heat Treatment Services Include

- Annealing: Softens materials for improved machinability and ductility.

- Normalizing: Refines grain structure to enhance toughness.

- Quenching: Increases hardness through rapid cooling.

- Tempering: Reduces brittleness while maintaining hardness.

- Stress Relieving: Minimizes residual stresses to prevent cracking.

- Carburizing: Hardens the surface while keeping a tough core.

- Induction Hardening: Improves wear resistance in specific areas.

Why Choose INSPECTA Middle East?

INSPECTA Middle East brings decades of experience and cutting-edge technology to the heat treatment process. Our team of skilled engineers and technicians work closely with you to understand the specific requirements of your project, ensuring that the heat treatment process is tailored to meet your exact needs.

We utilize state-of-the-art equipment and adhere to stringent quality standards to ensure that every heat-treated component meets or exceeds industry specifications. Whether you require heat treatment for large industrial components or specialized parts, INSPECTA is committed to delivering reliable, consistent results.

FAQ's

Q: What is heat treatment, and why is it important?

A: Heat treatment is a process that involves controlled heating and cooling of metals to alter their properties, enhancing strength, durability, and resistance to wear and corrosion.

Q: Which industries typically require heat treatment services?

A: Heat treatment is essential in industries like oil and gas, power generation, petrochemicals, automotive, and heavy manufacturing, where material performance under extreme conditions is critical.

Q: How does INSPECTA ensure the quality of its heat treatment services?

A: We use state-of-the-art equipment, adhere to strict quality standards, and employ experienced technicians to ensure every component meets or exceeds industry specifications.