Heat Treatment: Enhancing the Strength and Durability of Industrial Components

Introduction: Heat treatment is a fundamental process in the manufacturing and maintenance of industrial components. This blog will delve into the benefits of heat treatment, the various processes involved, and why it is essential for ensuring the longevity and performance of materials.

What is Heat Treatment? Heat treatment involves heating and cooling materials, typically metals, to alter their physical and sometimes chemical properties. The primary goal is to improve the material’s performance by increasing its strength, hardness, and resistance to wear.

Key Heat Treatment Processes

- Annealing: Softens the material, making it more ductile and improving its machinability.

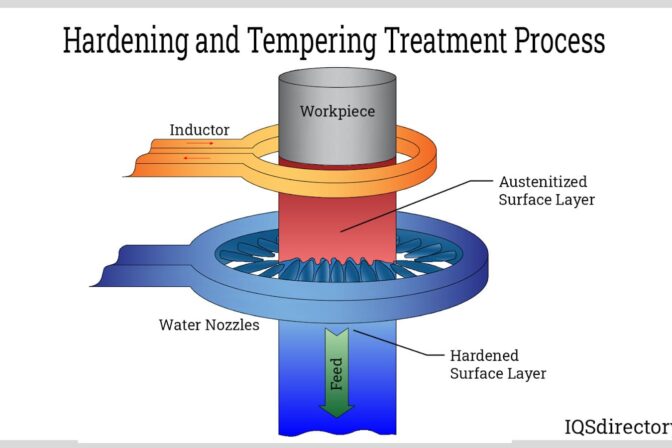

- Quenching: Increases hardness by rapidly cooling the material after heating.

- Tempering: Reduces brittleness in quenched steel, balancing hardness and toughness.

- Normalizing: Refines grain structure and improves mechanical properties.

Benefits of Heat Treatment: Heat treatment enhances the mechanical properties of materials, making them more suitable for their intended applications. It helps in improving wear resistance, fatigue strength, and overall durability, which is crucial for components used in high-stress environments.

INSPECTA’s Heat Treatment Services

INSPECTA Middle East offers a wide range of heat treatment services tailored to meet the specific requirements of different industries. Our state-of-the-art facilities and experienced team ensure that all processes are carried out with precision and efficiency.

Conclusion

Heat treatment is vital for enhancing the performance and lifespan of industrial components. By partnering with INSPECTA for your heat treatment needs, you are ensuring that your materials meet the highest standards of quality and durability.